Both employers and employees must know all the precautions to protect themselves against potentially hazardous conditions in grain handling facilities. Grain handling facilities are those such as grain elevators, feed mills, flour and rice mills, dry corn mills, dust palletizing plants, soybean flaking operations, and the dry grinding operations of soycake. Many safety and health hazards are associated with grain handling operations. Suffocation and falls are the two leading causes of death at grain handling facilities. Other risk factors are potential flash fires and explosions as a result of excessive amounts of airborne grain dust, and electrocutions and injuries from improperly guarded machinery. OSHA issued the grain handling facilities standard (29CFR 1910.272) to reduce injuries and deaths in the grain handling industry. This standard requires workers to be trained in the identification and control of grain handling hazards. Health and respiratory hazards are also presented by exposures to grain dust and airborne contaminants.

The most important facet of preventing health issues and injury risks in all industrial activities is proper training. Prior to new employees starting work, when changes occur in assignments, or if employees are exposed to new or unfamiliar hazards – the proper training must be applied. Also, when workers are assigned to infrequent, special, or suspected hazardous tasks (such as bin entry or handling toxic or flammable substances), they must have been trained correctly. Specific procedures included are performing housekeeping, hot work, lockout/tagout, and preventative maintenance. Grain handling facilities are required to implement a hot work permit system. This type of work includes electric or gas welding, cutting, grinding, brazing, or any similar activity that produces a flame or spark. The permit guarantees that the employer and operating personnel are aware that hot work is being performed and that accurate safety precautions have been taken.

We have talked about confined spaces in previous articles. In grain handling, there will be a necessity to enter silos, bins, and tanks. As mentioned before, atmospheric testing in confined spaces is mandatory. These tests must be conducted before entry (by experts) and continued until work is finished. Ventilation, supplemented by the use of appropriate air supplied respirators, shall be provided when: oxygen levels are less than 19.5%.

At home or work, it seems that housekeeping is extremely vital, especially so in industrial settings. OSHA standard allows “a maximum accumulation of no more than 1/8 inch of dust in priority housekeeping areas of grain elevators.” When this amount of grain dust accumulates, steps must be taken immediately for its removal. All lockout-tagout procedures required by 29 CFR 1910.147 and OSHA standard should be observed when entering grain elevators or silos for maintenance. If a person enters a bin, silo, or tank from the top, they must wear a full parachute-type body harness with a lifeline. This holds the body vertical and in case of an accident, makes easier removal of the victim through small access hatches. A well-trained and properly equipped attendant is required to maintain communication with the personnel in the confined area during the whole time, and to provide help when needed.

Workers in grain handling face serious dangers of suffocation, entanglement, falling, fires, explosions, electrocutions, and injuries from improperly guarded machinery. These dangers will be eliminated if employers implement a safe grain handling program, train their employees on the safe handling of grain, and both employer and workers carefully follow the procedures to ensure the safe handling of grain.

As we reported earlier, in an article about the Top Ten OSHA violations and penalties assessed for 2010, Violation of (29 CFR 1910.272) Grain Handling Facilities came in at #9 on the most penalties assessed list. At least 25 U.S. workers were killed in grain entrapments last year, and there were more grain entrapments in 2010 than in any other year since researchers at Purdue University began collecting data on the subject in 1978. The following is a list of violations that received citations, many of them classified as serious, in 2010:

- Failure to train in safety precautions and bin entry procedures;

- No observer during bin entry;

- No rescue equipment;

- Not testing atmosphere in the space to be entered;

- Failure to have deflagration controls for combustible dust;

- Walk working surfaces without guarding in place;

- Failure to safeguard employees from electrical hazards such as broken electrical conduits;

- Lack of signage and hazard communication procedures;

- Failure to evaluate work spaces for confined space entry permits;

- No confined space entry program;

- Non-entry retrieval system;

- Lack of personal protective equipment;

- Lack of electrical training;

- Lack of combustible dust controls;

- Failure to train employees in combustible grain dust hazards.

All workers should have the assurance that these things are not going to happen to them; that their company would purposely do everything possible to guarantee a safe return home after their shift every day. Let’s hope that 2011 will result in fewer violations and safer, well-informed and properly trained employees.

Source: OSHA, Texas Dept. of Insurance (TDI)

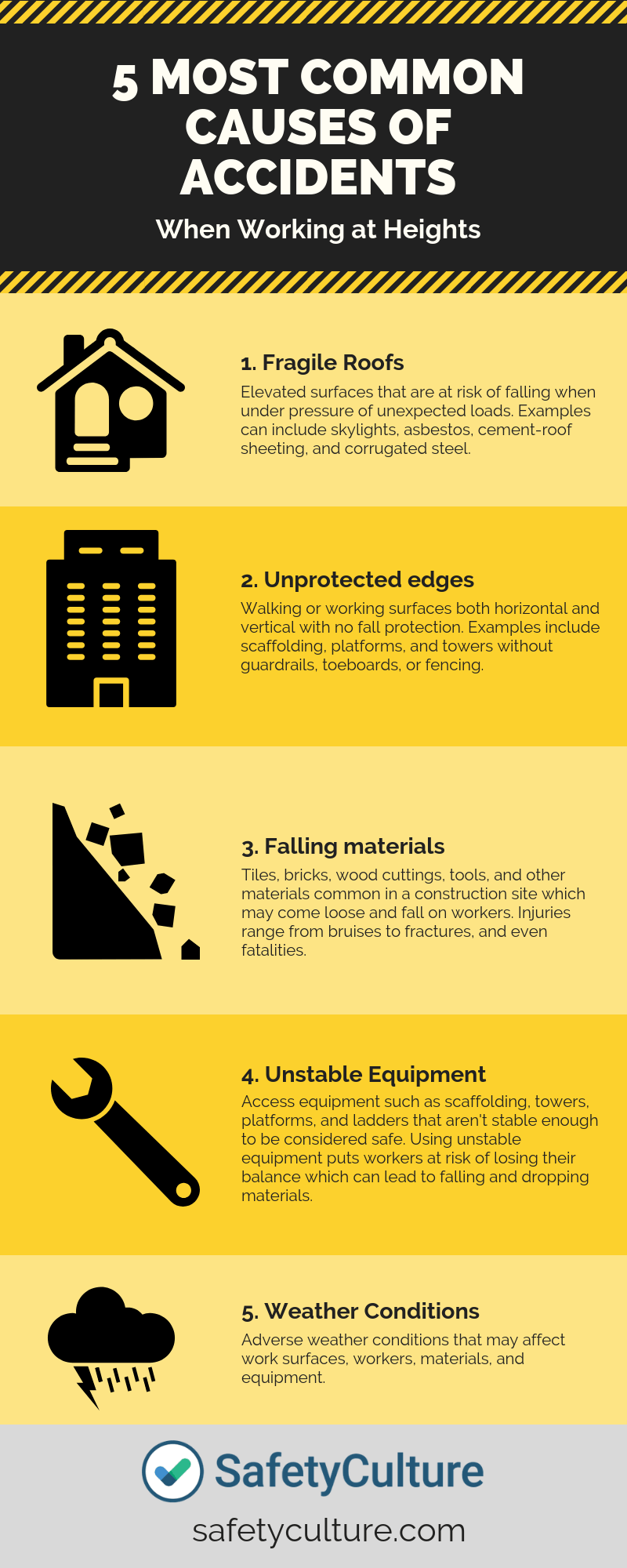

Simply providing the employees their monthly salary will not do. As an employer, you must take necessary steps to save them from any type of accident or injury. This is important from the point of workers’ safety and from the point of your business reputation as well. Worker’s law of your state is really strict and if any worker is injured while working, your business place may be shut down or you may have to give hefty amount as compensation. To avoid such circumstances, it is better to choose suitable height safety system. Workplace must be safe for working to ensure the well-being, health and safety of employees.

Simply providing the employees their monthly salary will not do. As an employer, you must take necessary steps to save them from any type of accident or injury. This is important from the point of workers’ safety and from the point of your business reputation as well. Worker’s law of your state is really strict and if any worker is injured while working, your business place may be shut down or you may have to give hefty amount as compensation. To avoid such circumstances, it is better to choose suitable height safety system. Workplace must be safe for working to ensure the well-being, health and safety of employees.