Top 7 Road Construction Work Zone Safety Tips

Whether you are traveling or constructing roads or houses – safety if the main focus point. We all agree on the statement that it is very important to have self-protection to be safe from any type of mishap respectively. There should be valid rules for the person who personally belongs to the construction field. It is very important to save them from any type of serious mishap respectively. As we all know very well that the field of construction is really needed to provide the complete safety precautions to their employees in the field so they can efficiently provide the best services in a better way.

Whether you are traveling or constructing roads or houses – safety if the main focus point. We all agree on the statement that it is very important to have self-protection to be safe from any type of mishap respectively. There should be valid rules for the person who personally belongs to the construction field. It is very important to save them from any type of serious mishap respectively. As we all know very well that the field of construction is really needed to provide the complete safety precautions to their employees in the field so they can efficiently provide the best services in a better way.

There are multiple options available in selecting the asphalt paving company if you need to maintain the best surface of the road. While paving the road there are different types of challenges which a professional company has to face. These challenges are as follows:

- Providing the best security solutions to the other people which provide them the safest way to pass through the under-construction area

- Place the signboards on the different sections of the road to notify people regarding the work in process notice

- Employees should wear the safety helmet and jacket to be easily recognized in the field

- Employees should spread the safety precautions to the vehicles and the pedestrians to avoid any type of serious injury

- It is compulsory to provide the alternative road to the people while the respective road is under-construction

- Work should be completed efficiently within a specified time of period

These things are very important to provide the common people the best safety precautions. Here we will discuss some important but useful tips for the asphalt pavers while completing the project respectively.

- Make a strong strategy

It is very much important to make a strong strategy while starting the paving process to build a strong road for the people. The suggested plan should be normal traffic control which will not disturb the people to reach their places. You should apply the best strategy to control the traffic in a way that people can easily pass through it. While operating the heavy machinery on the site you should have to maintain the area in such a way that will not disturb the normal traffic on the road.

- Make a proper plan for traffic control

It is compulsory to have the better plan to control the traffic area of the respective place. You can place the warning signs on the relevant places to update people about the construction process so they can also use the strategy for the respective place.

- Use cones to mark the area

As we all know very well that road construction areas really need to have care and precautions for the other traffic. This is why the best thing would be the road traffic cones on the respective area of the road which will directly indicate the traffic to use the diversions for the other safe route.

- Wear safety equipment

It is also very much important to wear the safety equipment on the construction site to identify yourself as a worker of the specific place. It will also notify the traffic to reduce the speed limit due to work in progress. It is very much important to wear the sharp colors equipment to notify people from a far distance.

- Use Helmet

The helmet is the most important equipment in this whole process to be safe from any type of serious injury. Usually, the helmet saves the person from any type of hard thing to get hit on the head. Head injury is the most crucial injury and could cause the death of the worker on the spot.

- Start your day with the new goals

When you will start the new day with updated goals you will definitely get the best result out of it. Driveway paving contractors will discuss the fresh updates with their whole crew and they also remind them to complete the task within a specified time period. It will also identify them about the things which they have to complete within a whole day.

- Make a site safety program

It is very important to provide the best safety to the people around you. You have to make a strategy to keep the other people safe from any type of mishap during the work in process. While making the construction program for the road, it is important to have the best ideas on how to keep other people safe from any type of disturbance. There should be valid spaces for the traffic which can easily be moved without any disturbance.

Photo Courtesy of

Photo Courtesy of

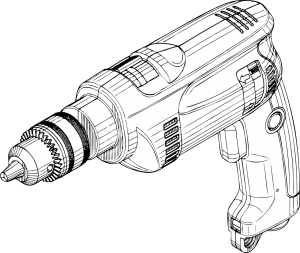

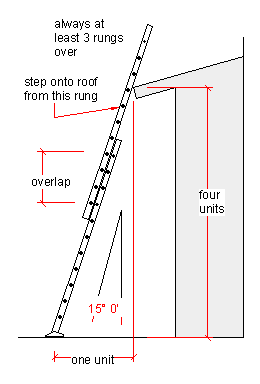

Ladder Safety

Ladder Safety

Simply providing the employees their monthly salary will not do. As an employer, you must take necessary steps to save them from any type of accident or injury. This is important from the point of workers’ safety and from the point of your business reputation as well. Worker’s law of your state is really strict and if any worker is injured while working, your business place may be shut down or you may have to give hefty amount as compensation. To avoid such circumstances, it is better to choose suitable height safety system. Workplace must be safe for working to ensure the well-being, health and safety of employees.

Simply providing the employees their monthly salary will not do. As an employer, you must take necessary steps to save them from any type of accident or injury. This is important from the point of workers’ safety and from the point of your business reputation as well. Worker’s law of your state is really strict and if any worker is injured while working, your business place may be shut down or you may have to give hefty amount as compensation. To avoid such circumstances, it is better to choose suitable height safety system. Workplace must be safe for working to ensure the well-being, health and safety of employees.